How to Calculate the Weight of Metal Panel?

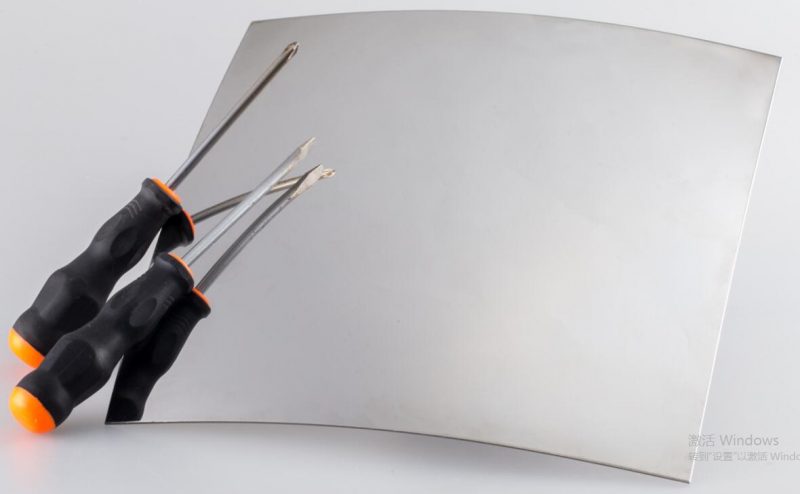

Metal materials like steel, aluminum, and stainless steel are the most used construction. It’s very important to know the precise weight of the metal panel or tube. On the one hand, precise weight of metal panel or tube is extremely important for big metal constructions, in the transport sector, and for lifting facilities. On the other hand, the weight also related to mechanical stress, such as move load, dead load or snow load etc.

The weight of plate is easy to calculate. Simply multiply the appropriate alloy density (see chart below) by the length, width, and thickness of the required part.

For an accurate calculation it is also important to allow for the rolling tolerance which affects the thickness and the cutting tolerances which affect the width and length.

Weight = L/1000 * W/1000 * T * S

L = Length in mm

W = Width in mm

T = Thickness in mm

S = Specific material density (Steel = 7.85 / Aluminum=2.70 )

EG: Aluminum panel (L: 1220mm, W: 2440mm, T: 3mm, S: 2.70)

W=1220/1000 * 2440/1000 * 3 *2.70

=24.11KGS

2.0mm thickness aluminum panel, 5.40kg/M2

2.5mm thickness aluminum panel, 6.78kg/M2

3.0mm thickness aluminum panel, 8.13kg/M2

| Metal | Density (Kg/M2) |

| Aluminum | 2.70 |

| Steel | 7.85 |

| Stainless steel | 7.93 |

| Brass | 8.52 |